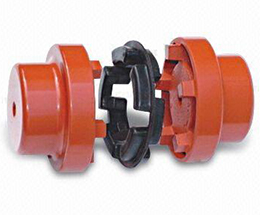

Introduction to NM Coupling for Simulation Equipment

Key Points:

- High Precision: NM coupling offers precise alignment and torque transmission for simulation equipment, ensuring smooth operation.

- Durability: With high-quality materials and advanced manufacturing processes, NM coupling is designed to withstand continuous use in simulation applications.

- Flexibility: NM coupling provides flexibility in design and installation, making it suitable for various simulation equipment setups.

Features of NM Coupling:

- High precision machining for accurate alignment

- Corrosion-resistant materials for durability

- Easy installation and maintenance

- Compact design for space-saving in simulation equipment

- Wide range of sizes and configurations available

Applications of NM Coupling:

NM coupling is ideal for simulation equipment due to the following advantages:

- Smooth torque transmission for precise motion simulation

- High durability for long-term use in demanding simulation environments

- Easy installation and alignment for quick setup

- Low maintenance requirements for continuous operation

- Cost-effective solution for simulation equipment manufacturers

Working Principle of NM Coupling:

The NM coupling works by transmitting torque from one shaft to another while allowing for misalignment and absorbing shocks and vibrations, resulting in smooth and reliable operation of simulation equipment.

Choosing the Right NM Coupling:

- Consider the torque requirements of the simulation equipment

- Choose the appropriate size and configuration for the application

- Ensure compatibility with shaft diameters and misalignment angles

- Check for corrosion-resistant materials for durability

- Consult with coupling experts for personalized recommendations

Maintenance of NM Coupling:

Regular maintenance of NM coupling is essential to ensure optimal performance and longevity of simulation equipment. It is important to lubricate moving parts, inspect for wear and tear, and address any issues promptly to prevent downtime and costly repairs.

About HZPT

HZPT, established in 2006, is a leading manufacturer and exporter specializing in coupling design, development, and production. With a dedicated team of designers and researchers for 16 years, we offer customized solutions to meet global customer requirements. Our products are CE and TUV certified, reflecting our commitment to quality and customer satisfaction. Choose HZPT for superior products, excellent service, and competitive prices in the mechanical industry.